Assorted Accessories

Drip Washers

The drip washer is a very small circular platform that adds more surface area to the bottom of self-feeding augers. The washer is designed to minimize or eliminate drip. The drip washer appears to be relatively insignificant but in fact it plays a huge role in controlling the drip of a non free flowing product. The drip washer comes in a variety of diameters and attaches to the end of the auger at the stem via a left handed screw and left handed thread tap. The drip washer has a beveled edge so that product does not stick to it. As the exiting product flows through the auger, the drip washer provides additional back pressure primarily caused by the inner lip of the funnel to keep the product compressed and less prone to drip.

Assorted Accessories

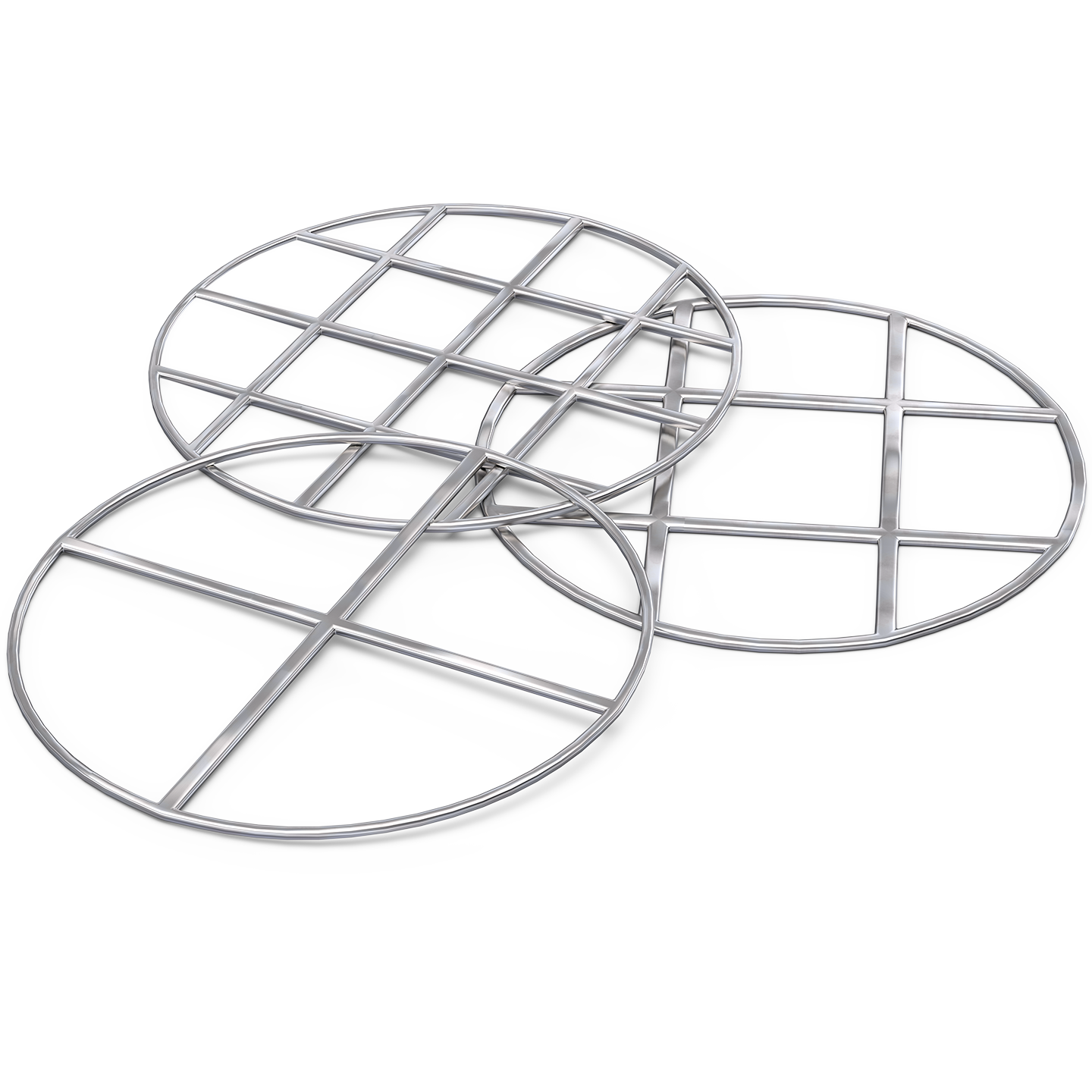

Restrictor Grids

The grid restrictor is similar to the drip washer however it is dropped from the top of the lip funnel and rests on the inside diameter of the lip. The grid adds more surface area for product to build up and minimize or eliminate drip. The grid restrictor is customized per each application but typically consists of interlocking grids, lines or stainless steel that are used to hold back the product while creating additional back pressure. The grid restrictor does not have to be rigid, oftentimes the grid restrictor can be made with string or wire and be called a “monofilament nozzle.”

Assorted Accessories

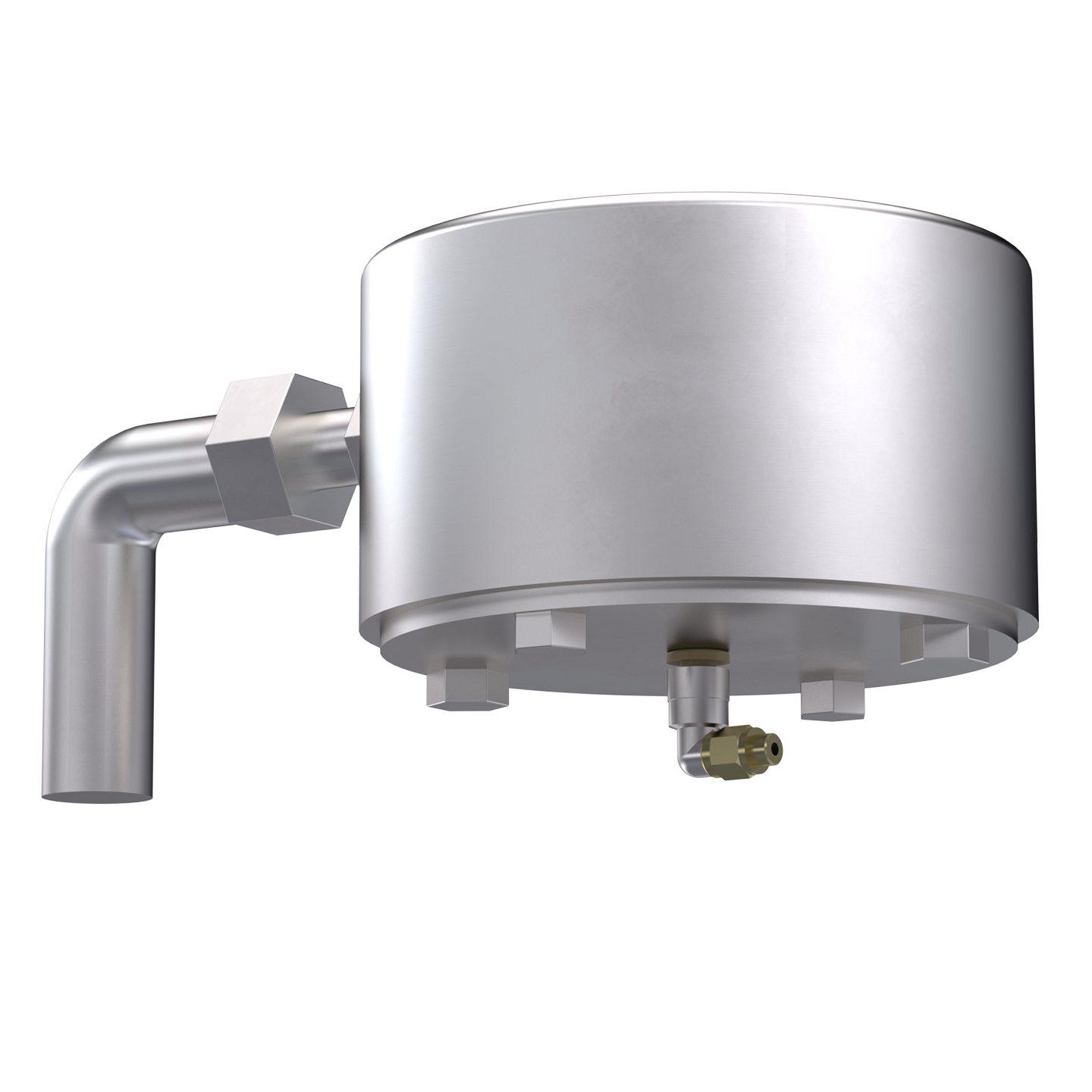

Clamp Rings

A clamp ring has a circular shape with an inner diameter that matches the outer diameter of the straight funnel's top portion. The clamp ring attaches the collector funnel cover to the straight funnel. Once the clamp ring is in position, it is tightened or secured using screws, bolts, or other fasteners. This creates a tight seal between the collector funnel cover and the straight funnel, ensuring that no material spills or leaks out during use.

Assorted Accessories

Dividing Heads

For the right application, a dividing head can be the perfect tool to increase fill rates. Most often, dividing heads are utilized for applications involving very free flowing products. The dividing heads can be made into segments of 2, 3 or 4 and are designed to sit below the auger in a free flow tooling set-up. The dividing head is ideally situated directly underneath the auger, perfectly centered. As the auger dispenses the product, the dividing head equally catches the product being discharged from the spinner plate. The product runs from the diving head through its individual nozzles into the container allowing the packager to fill multiple containers at once with only one auger. Assuming that product accuracy is acceptable, the dividing head provides a cheap and easy mechanical way increase production rates.

Assorted Accessories

Spinner Plates

The spinner plate is attached to the free-flowing auger via a left hand threaded bolt and a left hand nut(s), throws the product outward as a result of centrifugal force. Without the spinner plate, free flowing products will pass through the auger and funnel. The spinner plate stops product and with proper spacing between the end of the funnel and spinner plate, product is dispensed accurately into a collector funnel or dust shroud. The collector funnel nozzle is then sized to the opening of the customer’s container or bag.

Assorted Accessories

Agitation Blades

A slow-speed agitator blade bolts to the filler's slow-speed spindle assembly. The agitator blade is designed to best facilitate product flow into the pump rotor towards the center of the hopper where the auger is located. The blade rotates in the opposite direction as the auger and is cut to size depending on the size of the auger so that no product inside the hopper is stagnant. Flaky products such as oregano, which have a lighter density, may require the use of a flake blade rather than a traditional slow-speed blade. Flake blades rotate within the inner dimensions of the hopper allowing the product to fall inward towards the auger flights. The most common reason for using the flake blade is because the standard slow-speed blade often turns the mass of the product, meaning the blade cannot cut through the product so it all turns together.

Assorted Accessories

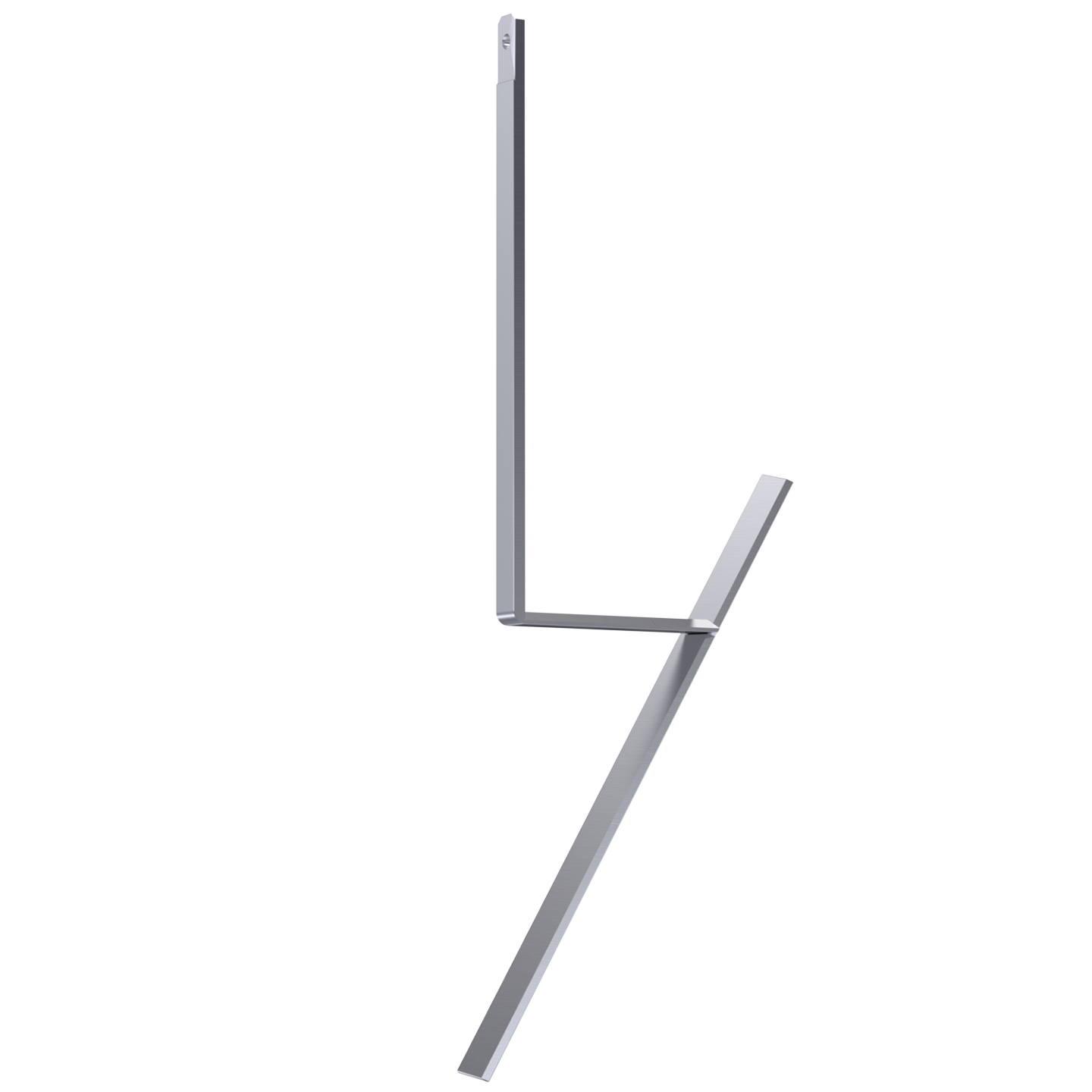

Cutoff Devices

Applications that require dispensing at multiple positions during a single fill cycle may use a Dividing Head assembly. The Dividing Head assembly is mounted on the column of the fillhead, beneath the hopper. Dividing Heads include a 2-way adjustment to “balance” the amount of product dispensed at each position. A typical Dividing Head assembly is shown in Figure 13.A Procedure describing how to adjust and balance Dividing Heads is contained in a Supplement to this publication.

Assorted Accessories

Left Hand Hardware

Left handed screws are used to attach drip washers to tapped holes in the bottom of self-feeding augers. Turn right to loosen or turn left to tighten. By using left-handed screws, the natural rotation of the auger during operation would tend to tighten the screws further, rather than loosening them, providing a more secure attachment of the drip washers.

We're easy to talk to for all inquiries, questions or comments. Complete the form and one of our sales representatives will contact you to further discuss your needs.