Auger Filler Tooling

Auger Fabrication Inc. manufactures high quality universal auger tooling accessories in a variety of styles including free-flowing, non-free-flowing, and liquid tooling.

There are three main styles of filling accessories, free-flowing (straight), non-free-flowing (self-feeding), or liquid tooling. These styles of universal tooling accessories are determined through product testing in our facility located in Downingtown, Pennsylvania. Lab testing is free of charge and our facility is equipped with a full range of augers, funnels, shafts, and other tooling accessories that our in-house lab technician can choose from in order to determine the best tooling sizes for our customer’s applications. Our auger filler tooling and funnels are manufactured from a variety of materials including; a variety of plastics, brass, carbon steel, cold roll steel, 304 & 316 stainless steel.

Free Flow Auger Universal Tooling

Straight augers are typically used for free-flowing powders such as granulated sugar, salt, bread crumbs, etc. They are commonly used with a slow speed or flake blade agitator, a straight funnel, collector funnel, and spinner plate. All parts are made in-house and designed to meet the delivery of the size auger and funnel combination. The purpose of this design is to allow the auger to meter product efficiently onto the spinner plate. Without the spinner plate, free-flowing products will pass through the auger and funnel. The spinner plate stops the product and with proper spacing between the end of the funnel and spinner plate, the product is dispensed accurately into a collector funnel or dust shroud. The collector funnel nozzle is then sized to the opening of the customer’s container or bag. Learn More.

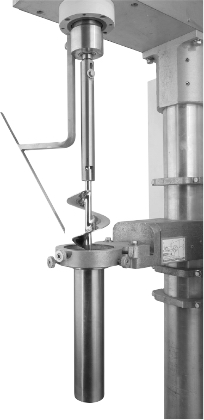

Non-Free Flow Auger Universal Tooling

Self-feeding augers are used for non-free-flowing powders such as bakery mixes, carbon, talcum powder, etc. They are commonly used with a slow-speed agitator, a high-speed “D” agitator blade, and a lip funnel. This type of auger is engineered differently than a straight auger. The top portion of the auger has over-flight. Over-flight is designed to grab and compact product evenly down through the straight section of the auger, dispensing product accurately. Lip funnels provide additional backpressure so that product does not drip from the auger. If a drip occurs because there isn’t enough back pressure to hold the product back, we would add different restrictors. Examples would be, drip washers, grid restrictors, monofilament nozzles, or cut-off assemblies. Learn More.

Liquid Universal Tooling

Viscous liquids and pastes products such as creams, shampoos, oils, gels, etc. can be dispensed with your filler using a shaft, U-joints, pump rotor, stator, and pump housings installed in place of the auger shaft, auger and funnel. Four different pump sizes are available, depending on capacity. For best results, there should be a 1/4” clearance between the pump and housing. Learn More.