Universal Tooling: A Quick Guide

Here is a quick guide to how each type of universal tooling works.

Universal Tooling

Even though there are endless amounts of applications that use Auger Fabrication's tooling, each one can be sorted into using one of three universal tooling types: Free-Flow, Non-Free-Flow, and Liquid. Auger Fabrication offers tooling that is universal, but it can also be built custom to your products specifications. Get in touch with us to find out how to maximize your tooling efficiency by calling us at (610) 524-3350 or chatting with us here on our website.

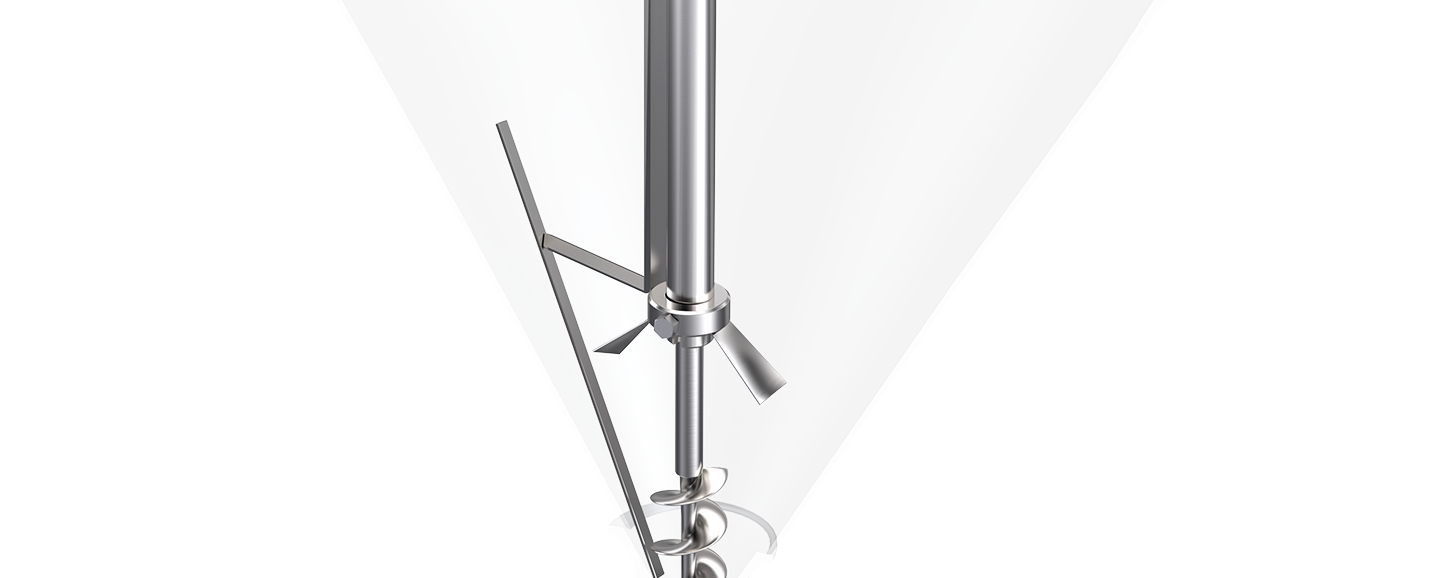

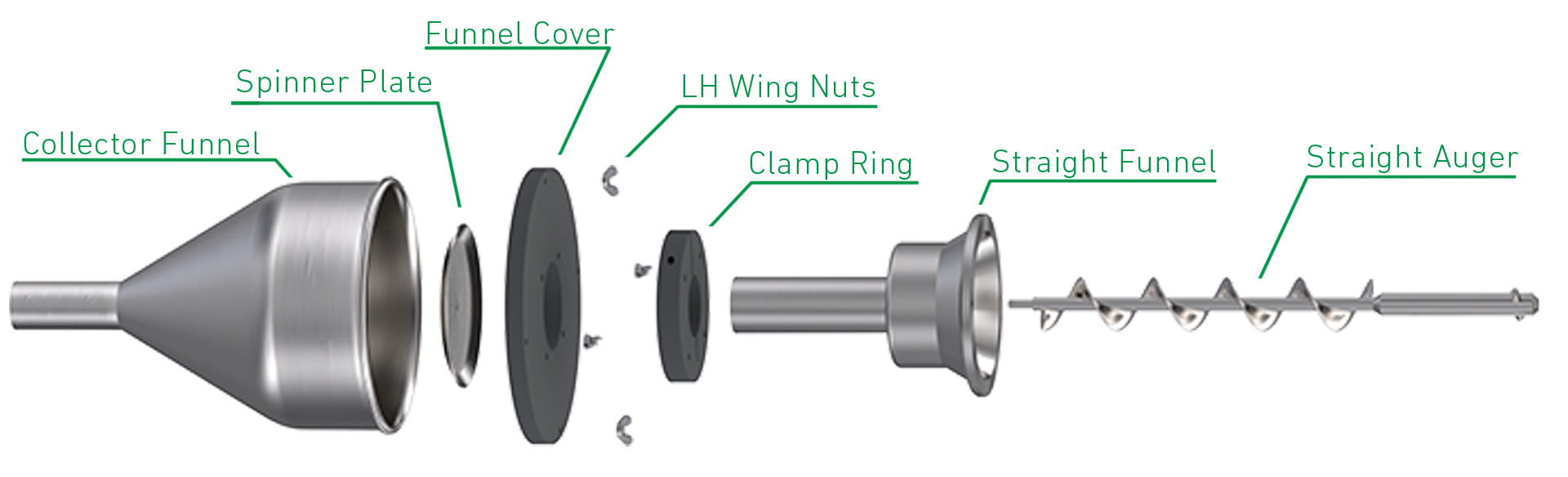

Free-Flow Tooling

For free-flowing products with low cohesion (such as salt, bread crumbs, or sand) typically requre a straight auger, an agitator, a straight funnel, collector funnel, and a spinner plate. This combination of parts allows for an efficient meter of products onto the spinner plate, which keeps product passing evenly into a container or bag.

Non-Free-Flow Tooling

Non-free-flowing products like flour, talcum powder, and baking mixes tend to clump together. They usually require a self-feeding auger, agitators, and a lip funnel. Occasionally, a drip washer may be required to prevent drip and help with the accuracy of dispending the product.

Liquid Tooling

Viscous liquids like gels, oils, and creams require a specific pump for dispensing. These pumps are a combination of a pump shaft, pump rotor, stator and pump housings. There are four sizes of pumps available according to your speicific application.